What is Machine Vision?

Definition and Overview

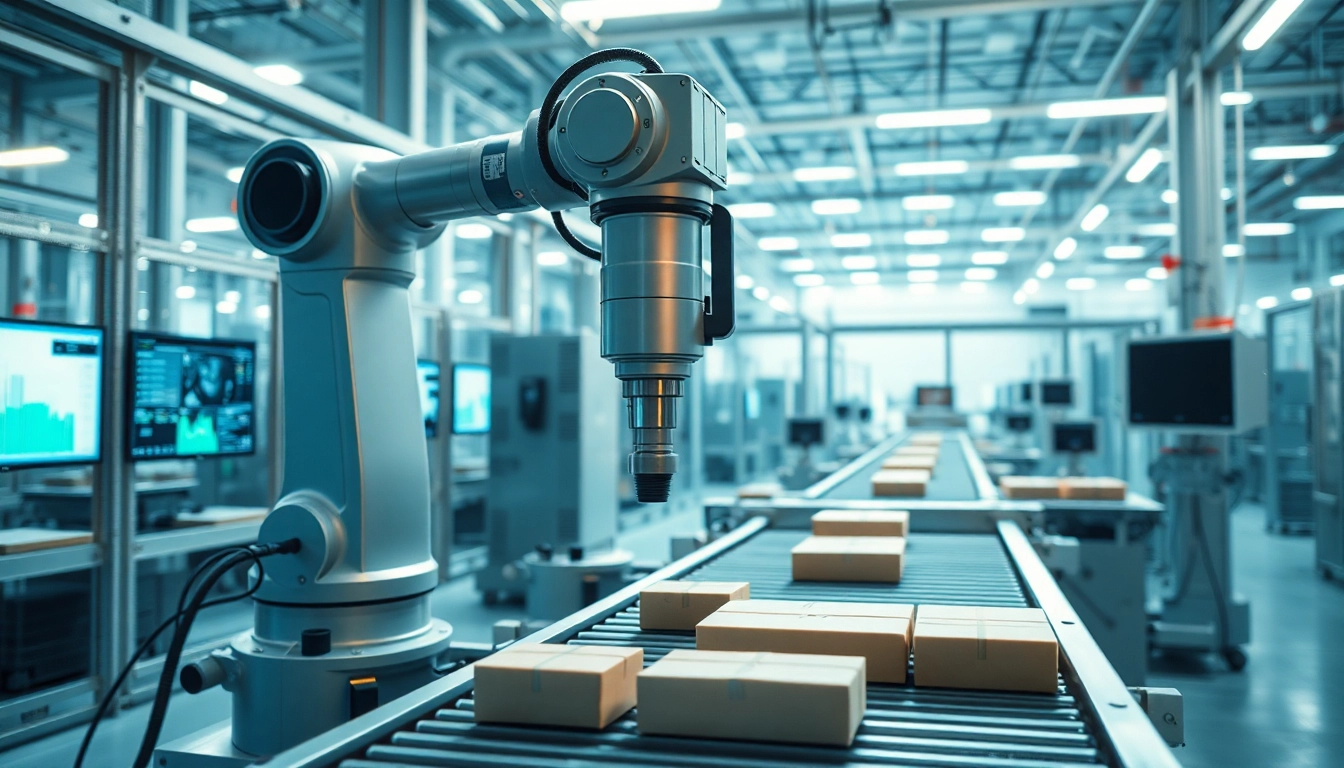

Machine vision is a technology that enables machines to interpret and understand visual information in a way that mimics human visual perception. It utilizes image acquisition, processing, and analysis to aid in automation and decision-making processes across a variety of industries. Often considered a subset of artificial intelligence (AI), machine vision integrates components such as cameras, lighting, and smart algorithms to perform tasks that would typically require human vision.

This technology is increasingly prevalent in industrial applications where precision and clarification of visual data are critical. It facilitates tasks like quality control, assembly line verification, and object detection. By systematically analyzing images captured by cameras, machine vision systems can autonomously detect anomalies, guide robotic movements, and optimize organizational workflows.

Key Components of Machine Vision Systems

A machine vision system consists of three primary components: hardware, software, and systems integration. Each plays a crucial role in ensuring the effective operation of the system.

- Cameras: These are the eyes of the machine vision system. They capture images of the object or scene being observed. The choice of camera—whether it be monochrome, color, or 3D—depends on the specific application requirements.

- Lighting: Proper lighting is essential for quality image acquisition. Different lighting techniques, such as backlighting, diffuse lighting, or structured lighting, are used to highlight features of interest and improve image clarity.

- Processing Software: After capturing an image, it is processed through specialized software that applies algorithms to analyze visual data. Software can perform tasks like edge detection, pattern recognition, and object classification, enabling machines to make informed decisions based on the data collected.

Additional components may include sensor technologies that enhance depth perception and enable 3D modeling, as well as communication protocols that facilitate interactions between different system components.

How Machine Vision Works

The operation of machine vision systems can be broken down into several distinct steps:

- Image Acquisition: Capturing images using optical sensors, cameras, or scanners. This step is crucial as the quality of the image will determine the reliability of the analysis.

- Image Preprocessing: Enhancing the captured image quality by removing noise, adjusting brightness or contrast, and preparing it for analysis. Techniques like filtering, thresholding, and histogram equalization may be employed.

- Feature Extraction: Identifying and isolating relevant features from the image such as edges, shapes, or textures that can be analyzed further. This step often involves complex algorithms that differentiate between features based on their characteristics.

- Analysis and Decision Making: Utilizing programmed rules or algorithms to interpret the identified features and make decisions. This could involve validating product quality, counting objects, or guiding robotic movement.

- Action: After analysis, the system can perform predetermined actions. This may include sending alerts, guiding robots for assembly, or adjusting machinery settings based on inspection results.

Applications of Machine Vision in Industry

Quality Control and Inspection

One of the most significant applications of machine vision is in quality control and inspection within manufacturing environments. The technology allows companies to detect defects and inconsistencies throughout the production process, ensuring that only products meeting quality standards reach the market. Common uses include:

- Defect Detection: Systems can rapidly identify surface defects, shape deviations, or dimensional inaccuracies during production, significantly reducing the chances of faulty products.

- Verification and Sorting: Machine vision can verify the presence and correct placement of components, ensuring proper assembly, as well as assist in sorting products based on specific attributes.

- Compliance Monitoring: Automated systems monitor compliance with industry standards and regulations by continuously analyzing product quality, thus reducing risks associated with violations.

Automation in Manufacturing

The integration of machine vision in manufacturing automation has revolutionized how systems operate, enhancing efficiency and reliability. With the aid of vision systems, machines can:

- Guide Robots: Machine vision technology allows robots to see and understand their environment, which is critical for tasks like pick-and-place operations, where the robot needs to identify specific objects.

- Optimize Workflows: By analyzing production lines in real-time, machine vision helps pinpoint bottlenecks and inefficiencies leading to continuous improvement of process workflows.

- Implement Predictive Maintenance: Observing machines’ visual data can indicate wear and predict failures, facilitating scheduled maintenance and minimizing downtime.

Machine Vision in Logistics and Supply Chain

In logistics and supply chain management, machine vision contributes significantly to streamlining processes and enhancing visibility within the supply chain. Key applications include:

- Barcode and QR Code Scanning: Automated systems equipped with machine vision can quickly read barcodes or QR codes, allowing for efficient tracking and inventory management.

- Package Inspection: Visual inspection systems can ensure that packages meet dimensional and label requirements, identifying those that require rework or rejection before shipping.

- Surveillance and Security: Machine vision serves as a valuable tool for monitoring warehouses and distribution centers, providing real-time insights into operations and ensuring security against theft or mishaps.

Advantages of Implementing Machine Vision

Increased Efficiency and Precision

The adoption of machine vision systems significantly enhances operational efficiency. By automating inspection processes, organizations can achieve:

- Faster Processing: Machine vision systems can analyze images in milliseconds, vastly outperforming human inspectors regarding speed.

- Consistent Quality Control: Automated systems provide uniformity in measurements and inspections, reducing variability and increasing product reliability.

- Reduction in Waste: By identifying defects early in the production cycle, organizations can significantly reduce waste associated with defective products, thus maximizing resource utilization.

Cost-Effectiveness Over Traditional Methods

Implementing machine vision technology can lead to substantial cost savings over time:

- Labor Costs: Automation allows for the reduction of labor costs associated with manual inspections. Organizations can reallocate human resources to more strategic tasks while reducing operational expenses.

- Lower Error Rates: By minimizing human errors, companies can avoid costly rework or returns, contributing to a more efficient bottom line.

- Scalability: Machine vision systems can easily scale as operations expand, providing a future-proof solution that adapitates to higher production needs without steep increases in operational costs.

Improved Data Collection and Analysis

Machine vision systems not only capture images but also generate valuable data. This data can be analyzed to provide insights into:

- Performance Metrics: Analysis of visual data enables organizations to identify performance trends and assess the efficiency of manufacturing processes.

- Predictive Analytics: Insights drawn from machine vision can pave the way for predictive analyses, allowing businesses to foresee potential issues before they escalate.

- Real-Time Monitoring: Data collected can be used for real-time analytics, allowing immediate feedback and adjustments in production workflows, leading to enhancements in overall quality.

Challenges and Considerations

Integration with Existing Systems

Integrating machine vision systems into existing production lines can pose a number of challenges:

- Compatibility Issues: Legacy systems may not easily interface with modern machine vision technologies, necessitating a careful assessment of how new systems will integrate with current equipment.

- Specialized Training: Employees may require training to operate and troubleshoot new machine vision technologies effectively, adding to initial implementation costs.

- Workflow Adjustments: The incorporation of machine vision may necessitate workflow adjustments that impact the entire production line, requiring careful planning and execution.

Cost and Investment Considerations

The initial investment for machine vision systems can be substantial, encompassing cameras, lighting, software, and integration costs. Organizations should consider:

- Long-Term Return on Investment (ROI): While upfront costs can be high, understanding the long-term savings and benefits can help justify the investment.

- Budgeting for Maintenance and Upgrades: Regular maintenance and potential upgrades to keep the systems functioning efficiently should be factored into financial planning.

- Choosing the Right Technology: Choosing between different types of vision technologies (2D vs. 3D imaging) can impact cost and effectiveness; therefore, a thorough assessment based on specific requirements is essential.

Technological Advancements and Future Trends

The machine vision landscape is evolving rapidly, driven by technological advancements that enhance capabilities and applications. Future trends include:

- Increased AI Integration: The incorporation of AI and machine learning algorithms will allow for more sophisticated image analysis, enabling advanced capabilities like anomaly detection and predictive maintenance.

- Edge Computing: As industries lean towards distributed computing to handle data processing near the data source, edge computing will enable real-time analysis without the need for constant cloud communication.

- Augmented Reality (AR) and Virtual Reality (VR): Machine vision systems may increasingly incorporate AR and VR technologies for enhanced training and operational simulations.

Conclusion and Future Outlook on Machine Vision

Summary of Key Insights

Machine vision is reshaping industrial landscapes by allowing machines to interpret visual data and make automated decisions. This technology does not only streamline workflow processes but also enhances quality control and overall efficiency. The components that make up machine vision systems—including cameras, lighting, and processing software—are pivotal for accurate image analysis. As machine vision becomes more integrated into various sectors, its applications extend from manufacturing to logistics and beyond.

Future Innovations in Machine Vision

The future of machine vision is bright, with continuous advancements expected in AI integration, real-time data processing, and automation. As machine perception technology improves, organizations will benefit from smarter systems that require minimal downtime and constant monitoring. These innovations are likely to lead to broader adoption across sectors, catering to complex requirements while maintaining cost efficiency.

Final Thoughts on Industry Adoption

The pressing need for automation, quality assurance, and data-driven decision-making will drive the adoption of machine vision technology further in the coming years. Businesses not yet leveraging this powerful technology should assess its potential benefits to stay competitive in an increasingly automated world. As machine vision systems advance, their integration will play a pivotal role in enhancing operational productivity and product quality.