Understanding Structural Steel Fabrication

Definition and Importance of Structural Steel Fabrication

Structural steel fabrication is the process involved in cutting, shaping, and assembling steel to create structures that are both functional and visually appealing. This technique is crucial in the construction industry as it contributes significantly to infrastructure development, including bridges, buildings, frames, and various other architectural elements. The fabrication process employs advanced technology and intricate methodologies, ensuring that the final products meet strict quality and safety standards.

By utilizing structural steel fabrication, builders can ensure durability, strength, and resilience in construction projects. This method allows for adaptations to unique structural designs, thereby providing flexibility in architectural aesthetics while maintaining safety and compliance with construction regulations.

Common Applications in Construction and Engineering

The applications of structural steel fabrication are diverse and expanding daily. Key applications include:

- Residential Construction: Fabricated steel is used in homes for support beams, frames, and roofing structures, offering both strength and design flexibility.

- Commercial Buildings: In office complexes, shopping centers, and warehouses, structural steel provides the necessary support to large spaces, allowing for expansive floor plans.

- Industrial Facilities: Factories and industrial plants utilize steel frameworks for durability under heavy machinery and equipment.

- Infrastructure Projects: Bridges, tunnels, and highways heavily rely on steel fabrication for structural integrity and longevity.

- Renovation Projects: Often, existing structures require upgrades or modifications, where structural steel memory can provide the necessary reinforcement and redesign capabilities.

Key Materials Used in Structural Steel Fabrication

Several materials form the backbone of structural steel fabrication, which are critical for achieving desired strength and performance. Some of the primary materials include:

- Steel Alloys: These are mixtures of steel and other elements, enhancing properties like corrosion resistance and strength.

- Stainless Steel: Known for its durability and aesthetic appeal, stainless steel is used especially where exposure to weather and chemicals is a concern.

- High-Strength Low-Alloy (HSLA) Steel: This type of steel is beneficial for structures needing to withstand extreme loads while being lighter than traditional steel.

- Reinforcing Bars: Commonly used alongside steel fabrications to provide additional support in concrete structures.

- Composite Materials: These involve combinations of steel with other materials to form composite structures that leverage the advantages of both.

The Structural Steel Fabrication Process

Overview of the Fabrication Stages

The structural steel fabrication process involves several critical stages that ensure precision and quality. The stages typically include:

- Design Phase: Involves architects and engineers collaborating to create detailed plans and specifications based on the project’s requirements.

- Material Procurement: Sourcing and acquiring raw materials from suppliers, ensuring they meet required standards and specifications.

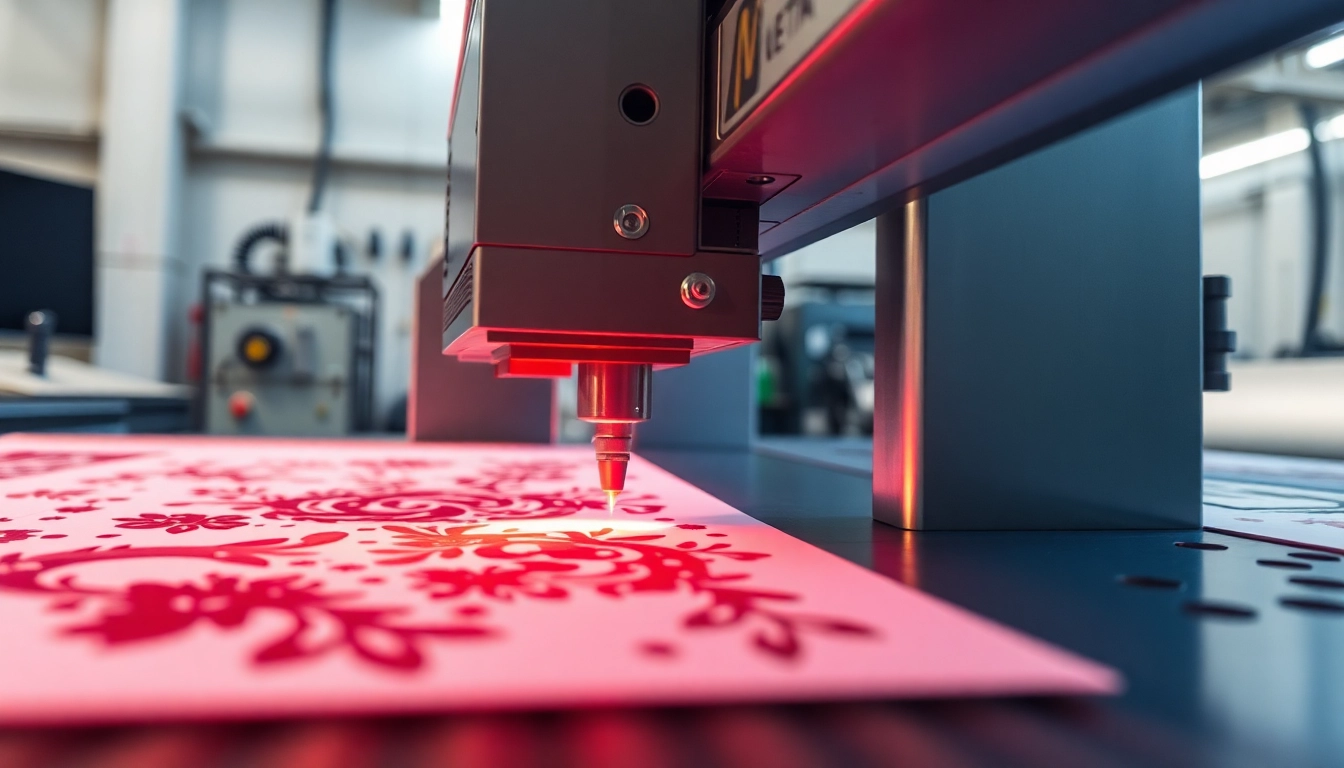

- Cutting: Utilizing advanced machinery, like CNC cutting tools, to precisely cut the steel according to design outlines.

- Bending: This stage incorporates equipment that can bend steel into various shapes needed for the project.

- Assembling: The fabricated pieces are assembled into larger components, often in a workshop setting before moving to the site.

- Finishing Treatments: Applying coatings or treatments to enhance durability and protect against environmental factors.

- Quality Control: Ensuring that the fabrication meets predefined quality standards through inspections and checks.

- Delivery and Installation: Finally, the assembled structures are transported to the construction site for installation, ensuring all components fit together correctly.

Cutting, Bending, and Assembling Techniques

The execution of cutting, bending, and assembling techniques is critical for achieving high-quality structural steel fabrication. Each technique employs specialized tools:

- Cutting Techniques: Precision cutting methods, such as water jet cutting, laser cutting, and plasma cutting, allow for accurate shapes to be formed, reducing waste and enhancing detail.

- Bending Techniques: Bending involves equipment such as press brakes and roll benders, which can manipulate steel to the required curvature and angle necessary for specific designs.

- Assembly Techniques: Assemblies may involve welding techniques, bolting, or riveting, with each method having its advantages. Automatic welding machines have revolutionized this process by increasing speed and consistency.

Safety Measures During Structural Steel Fabrication

Safety is paramount during the structural steel fabrication process. Companies are required to implement numerous safety measures, including:

- Protective Gear: Mandatory use of helmets, gloves, goggles, and other protective apparel to safeguard against accidents.

- Training Programs: Regular training sessions for workers ensure everyone is aware of the dangers and understands safety protocols.

- Emergency Protocols: Establishing clear emergency response plans in case of accidents or equipment failures.

- Regular Equipment Inspections: Ensuring machinery is regularly checked and maintained to avoid malfunctions that could lead to hazards.

Cost Analysis of Structural Steel Fabrication

Factors Influencing Fabrication Costs

The costs involved in structural steel fabrication can vary significantly based on several influential factors, including:

- Material Costs: The price of raw materials fluctuates according to market demand, availability, and quality.

- Labor Costs: Highly skilled labor may demand higher wages, impacting overall fabrication costs depending on project complexity.

- Shop Overhead: Includes costs associated with running the facility, such as utilities, equipment maintenance, and operational expenses.

- Project Scope: The larger and more complex the project, the higher the costs associated with fabrication, as more resources and time will be required.

Budgeting for Structural Steel Projects

Strategically budgeting for structural steel projects entails accurate forecasting of all expenses. Effective budgeting practices include:

- Detailed Project Estimates: Analyzing historical data from past projects to develop accurate cost estimates.

- Contingency Funds: Allocating additional funds for unforeseen issues or changes during the fabrication process.

- Regular Budget Reviews: Consistently reviewing budget versus actual expenditures helps in identifying any discrepancies early on.

Analyzing Return on Investment

Evaluating the return on investment (ROI) for structural steel projects involves considering both tangible and intangible benefits:

- Quality and Durability: Investments in high-quality steel often lead to lower repair costs over time, enhancing ROI.

- Speed of Construction: Faster construction times can lead to quicker project completions, positively impacting financial returns.

- Aesthetic Appeal: Well-fabricated structures can attract higher rental or resale values in the real estate market.

Best Practices for Effective Structural Steel Fabrication

Quality Control Measures

Implementing strict quality control measures is crucial in ensuring the integrity of structural steel fabrications. These measures may include:

- Standardized Testing: Regularly testing materials and finished products for compliance with industry standards.

- Documentation: Keeping thorough records of all fabrication processes for future reference as well as compliance verification.

- Audits and Inspections: Conducting periodic inspections and audits of products and processes to identify areas of improvement.

Streamlining Workflows with Technology

Technology plays a vital role in enhancing the efficiency and accuracy of structural steel fabrication. Key methods include:

- CNC machines: Introduced to automate cutting and shaping processes, thereby increasing precision and reducing labor costs.

- BIM Technology: Building Information Modeling (BIM) offers a digital representation of physical and functional characteristics, improving collaboration and reducing errors.

- Project Management Software: Utilizing software solutions for better project tracking, budgeting, and resource allocation leads to a higher success rate in project delivery.

Choosing Reliable Suppliers and Partners

Successful structural steel fabrication hinges not just on internal practices but also on choosing the right suppliers and partners. Factors to consider include:

- Reputation: Assessing previous projects, client testimonials, and industry ratings to gauge supplier reliability.

- Quality Assurance: Opting for suppliers who comply with recognized standards and consistently deliver high-quality materials.

- Responsive Communication: Evaluating potential partners on their communication effectiveness, especially during project changes or challenges.

Future Trends in Structural Steel Fabrication

Innovations in Fabrication Techniques

The structural steel fabrication industry is continually evolving, with innovations driving efficient and sustainable practices. Trends include:

- 3D Printing: Utilizing additive manufacturing technology for creating complex steel components on demand.

- Robotics: Implementing robotic welders and assembly systems to improve efficiency and accuracy.

- Smart Manufacturing: Incorporating IoT devices for real-time data collection to optimize manufacturing processes.

Sustainability Practices in the Industry

With growing concerns over environmental impact, the structural steel industry is increasingly focusing on sustainability:

- Recycling Materials: Implementing processes to recycle steel, minimizing waste and reducing the need for new materials.

- Energy Efficiency: Adopting energy-efficient production practices and sourcing renewable energy for operations.

- Life Cycle Assessment: Using tools to evaluate environmental impacts throughout the lifecycle of steel products.

Adapting to New Regulations and Standards

As the construction industry evolves, new regulations and standards emerge. Fabricators must ensure compliance by:

- Continuous Education: Keeping abreast of the latest building codes, safety regulations, and industry standards.

- Collaboration with Regulatory Bodies: Engaging with local and national regulatory bodies to ensure ongoing compliance.

- Implementing Best Practices: Establishing industry best practices within organizations to meet and exceed compliance requirements.